Brake System Restoration: Ensuring Safe Stops

Ensure safe stops in your classic car by restoring its brake system. Learn about replacing brake pads, rotors, and calipers. Improve braking performance and safety.

Why Brake System Restoration is Crucial for Classic Cars

Hey there, classic car enthusiast! Let's talk about something super important: your brakes. We're not just talking about stopping; we're talking about *safely* stopping in your vintage beauty. A well-maintained brake system is absolutely essential for the safety of you, your passengers, and everyone else on the road. Classic car brakes, due to their age and potentially outdated technology, need extra attention. Restoring them isn't just about aesthetics; it's about ensuring you can handle modern traffic conditions and unexpected situations with confidence.

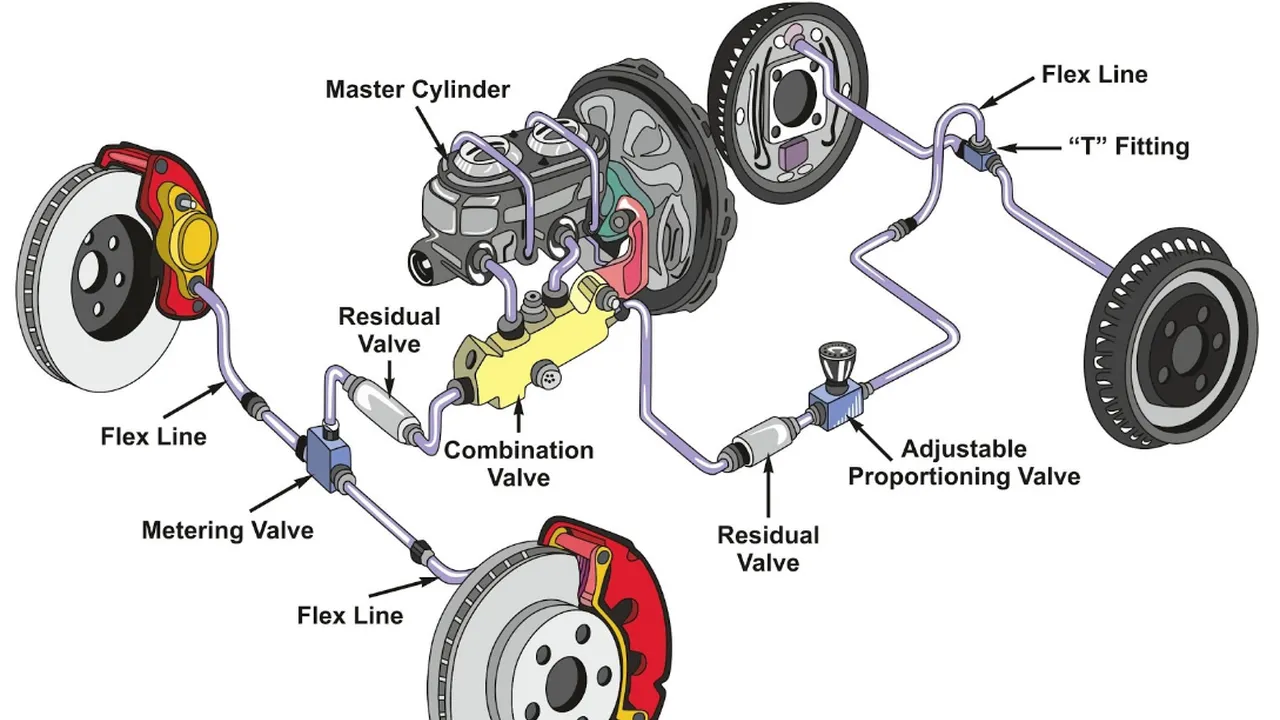

Understanding the Components of Your Classic Car's Brake System

Before we dive into the restoration process, let's quickly review the main parts of your classic car's brake system. This will help you understand what needs to be inspected and potentially replaced.

- Master Cylinder: This is the heart of your brake system. It's a reservoir that holds brake fluid and uses a piston to create hydraulic pressure when you press the brake pedal.

- Brake Lines: These lines carry the brake fluid from the master cylinder to the brake calipers or wheel cylinders.

- Brake Calipers (Disc Brakes): Calipers house the brake pads and use pistons to squeeze the pads against the rotors, creating friction to slow down the wheels.

- Wheel Cylinders (Drum Brakes): Found in drum brake systems, wheel cylinders use hydraulic pressure to push the brake shoes against the brake drums.

- Brake Rotors (Disc Brakes): These are metal discs that rotate with the wheels. The brake pads clamp onto the rotors to slow them down.

- Brake Drums (Drum Brakes): These are metal drums that rotate with the wheels. The brake shoes press against the inside of the drums to slow them down.

- Brake Pads: These are friction materials that press against the rotors (in disc brakes) to create friction.

- Brake Shoes: These are friction materials that press against the inside of the drums (in drum brakes) to create friction.

- Brake Hoses: Flexible hoses that connect the brake lines to the calipers or wheel cylinders, allowing for suspension movement.

- Parking Brake System: A separate system, usually cable-operated, used to keep the car stationary when parked.

Essential Steps for Classic Car Brake System Restoration

Now, let's get down to the nitty-gritty. Here's a step-by-step guide to restoring your classic car's brake system:

- Inspection: Start with a thorough inspection of all brake components. Look for leaks, cracks, rust, and wear. Pay close attention to the brake lines, hoses, master cylinder, calipers/wheel cylinders, rotors/drums, and brake pads/shoes.

- Master Cylinder Rebuild or Replacement: If the master cylinder is leaking or showing signs of wear, rebuild it with a rebuild kit or replace it entirely. Rebuilding is often cheaper, but replacement ensures optimal performance.

- Brake Line and Hose Replacement: Replace all brake lines and hoses, especially if they are original. Rubber hoses degrade over time and can crack, leading to brake failure. Consider stainless steel brake lines for increased durability and improved braking feel.

- Caliper/Wheel Cylinder Rebuild or Replacement: Rebuild or replace calipers (disc brakes) or wheel cylinders (drum brakes). Rebuilding involves disassembling them, cleaning the components, and replacing the seals. Again, replacement is a more reliable option.

- Rotor/Drum Refacing or Replacement: Have the rotors (disc brakes) or drums (drum brakes) refaced if they are warped or have uneven wear. If they are too thin or damaged, replace them.

- Brake Pad/Shoe Replacement: Replace brake pads (disc brakes) or shoes (drum brakes) with new ones. Choose high-quality friction materials that are appropriate for your driving style and the type of brakes your car has.

- Brake Hardware Replacement: Replace all brake hardware, including springs, clips, and adjusters. These small parts are essential for proper brake function.

- Brake Fluid Flush and Bleeding: Flush the entire brake system with fresh brake fluid. Bleed the brakes to remove any air bubbles, which can compromise braking performance.

- Parking Brake Adjustment: Adjust the parking brake system to ensure it is functioning properly.

- Testing: After completing the restoration, thoroughly test the brakes in a safe environment. Check for proper pedal feel, stopping power, and any unusual noises.

Choosing the Right Brake Pads for Your Classic Car

Selecting the right brake pads is crucial for optimal braking performance. Here's a breakdown of common brake pad types and their applications:

- Organic Brake Pads: These are made from organic materials like rubber, carbon, and fiberglass. They are quiet and produce less dust, but they wear out faster and are not ideal for high-performance driving.

- Semi-Metallic Brake Pads: These contain a mix of metallic and organic materials. They offer a good balance of performance, durability, and noise. They are a popular choice for classic cars.

- Ceramic Brake Pads: These are made from ceramic fibers and offer excellent braking performance, low noise, and long lifespan. They are more expensive than organic or semi-metallic pads.

- Metallic Brake Pads: These are made primarily from metal. They offer excellent braking performance, especially in high-performance applications, but they can be noisy and wear out rotors faster. Not typically recommended for most classic car applications unless specifically needed for performance.

Recommendation: For most classic cars, semi-metallic brake pads offer a good balance of performance and affordability. Consider ceramic pads if you want the best possible braking performance and are willing to pay a premium.

Comparing Brake Pad Brands: A Quick Look

Let's take a look at some popular brake pad brands and what they offer:

- Raybestos: A well-known brand offering a wide range of brake pads for various vehicles, including classic cars. They are known for their quality and reliability.

- Wagner: Another reputable brand that offers a variety of brake pads, including semi-metallic and ceramic options. They are known for their innovation and performance.

- EBC Brakes: A popular brand among enthusiasts, EBC offers a wide range of brake pads, including high-performance options. They are known for their quality and performance.

- Power Stop: Specializes in performance brake kits, often including rotors and pads designed to work together for improved stopping power. Good choice if you're upgrading your entire brake system.

Specific Brake Pad Recommendations with Pricing (Approximate)

Keep in mind that pricing can vary depending on the specific vehicle and retailer.

- Raybestos Service Grade Semi-Metallic Brake Pads: A good all-around choice for classic cars. Offers reliable stopping power and decent wear. Price: $20-$40 per set.

- Wagner ThermoQuiet Semi-Metallic Brake Pads: Known for their quiet operation and good performance. A solid choice for daily driving. Price: $30-$50 per set.

- EBC Brakes Greenstuff 2000 Series: A popular upgrade for classic cars. Offers improved braking performance over stock pads. Price: $50-$70 per set.

Upgrading to Disc Brakes: A Worthwhile Investment?

Many classic cars originally came with drum brakes, which are less effective than disc brakes. Upgrading to disc brakes can significantly improve your car's stopping power and safety. However, it's a more involved and expensive process.

Pros of Upgrading to Disc Brakes:

- Improved stopping power

- Better heat dissipation

- Less prone to brake fade

- More consistent performance

Cons of Upgrading to Disc Brakes:

- Higher cost

- More complex installation

- Potential modifications to the car's suspension or wheels

Recommendation: If you plan on driving your classic car frequently or in demanding conditions, upgrading to disc brakes is a worthwhile investment. If you primarily drive your car for occasional shows or leisurely cruises, the original drum brakes may be sufficient after a thorough restoration.

Specific Product Recommendations for Disc Brake Conversion Kits with Pricing (Approximate)

- Master Power Brakes Disc Brake Conversion Kit: A popular and well-regarded kit for various classic cars. Includes everything you need for a complete conversion. Price: $800-$1500, depending on the vehicle.

- Wilwood Disc Brakes: Known for their high-performance braking systems. Offers conversion kits for specific classic car models. Price: $1000-$2000, depending on the vehicle.

- The Right Stuff Detailing: Offers a variety of disc brake conversion kits and components for classic cars. Known for their quality and accurate reproductions. Price: $700-$1400, depending on the vehicle.

The Importance of Brake Fluid: Choosing the Right Type

Brake fluid is a crucial component of your brake system, and choosing the right type is essential. Here's a quick overview of common brake fluid types:

- DOT 3: A common brake fluid type that is compatible with most classic cars.

- DOT 4: Offers a higher boiling point than DOT 3, making it more resistant to brake fade.

- DOT 5: A silicone-based brake fluid that is not compatible with all brake systems. It is not hygroscopic (does not absorb moisture), but it can be more difficult to bleed.

- DOT 5.1: A synthetic brake fluid that offers a high boiling point and is compatible with most brake systems.

Recommendation: For most classic cars, DOT 3 or DOT 4 brake fluid is a good choice. DOT 4 offers slightly better performance, especially in demanding conditions. Avoid using DOT 5 unless your brake system is specifically designed for it.

Tools and Equipment for Brake System Restoration

To properly restore your classic car's brake system, you'll need a few essential tools and equipment:

- Brake Bleeder Kit: For bleeding the brakes after flushing the system.

- Flare Nut Wrenches: For loosening and tightening brake line fittings without damaging them.

- Brake Spring Tool: For removing and installing brake shoe springs (drum brakes).

- Caliper Piston Compressor: For compressing caliper pistons when installing new brake pads (disc brakes).

- Torque Wrench: For tightening brake components to the correct specifications.

- Jack and Jack Stands: For safely lifting and supporting the car.

- Safety Glasses and Gloves: For protecting your eyes and hands.

Safety First: Essential Precautions When Working on Brakes

Working on brakes can be dangerous if you're not careful. Here are some essential safety precautions to keep in mind:

- Always wear safety glasses and gloves.

- Work in a well-ventilated area.

- Never work under a car that is only supported by a jack. Use jack stands.

- Use the correct tools for the job.

- Dispose of used brake fluid properly.

- If you are not comfortable working on brakes, seek professional help.

Troubleshooting Common Brake Problems

Even after a restoration, you may encounter brake problems. Here are some common issues and how to troubleshoot them:

- Spongy Brake Pedal: Usually caused by air in the brake lines. Bleed the brakes.

- Brake Fade: Loss of braking power due to overheating. Upgrade to better brake pads or rotors.

- Brake Squeal: Can be caused by worn brake pads, glazed rotors, or loose hardware. Inspect and replace worn components.

- Pulling to One Side: Can be caused by a sticking caliper, uneven brake pad wear, or a problem with the suspension. Inspect and repair the brakes and suspension.

- Brake Fluid Leak: Inspect brake lines, hoses, master cylinder, calipers, and wheel cylinders for leaks. Replace damaged components.

Maintaining Your Restored Brake System

Once you've restored your classic car's brake system, it's important to maintain it properly to ensure its longevity and performance:

- Regularly inspect the brake system for leaks, wear, and damage.

- Flush the brake fluid every two years.

- Replace brake pads and shoes as needed.

- Have the rotors and drums refaced or replaced as needed.

So there you have it! Restoring your classic car's brake system is a crucial investment in your safety and the longevity of your vehicle. By following these steps and choosing the right components, you can ensure safe and reliable stopping power for years to come. Happy wrenching!

:max_bytes(150000):strip_icc()/277019-baked-pork-chops-with-cream-of-mushroom-soup-DDMFS-beauty-4x3-BG-7505-5762b731cf30447d9cbbbbbf387beafa.jpg)